Potable Water Supply

HDPE Pipes & Coils IS: 4984:1995

MATERIALS

It is made of either of three grades of High Density Poly Ethylene polymers. i.e PE-63, PE-80 or PE-100

PRODUCT RANGE

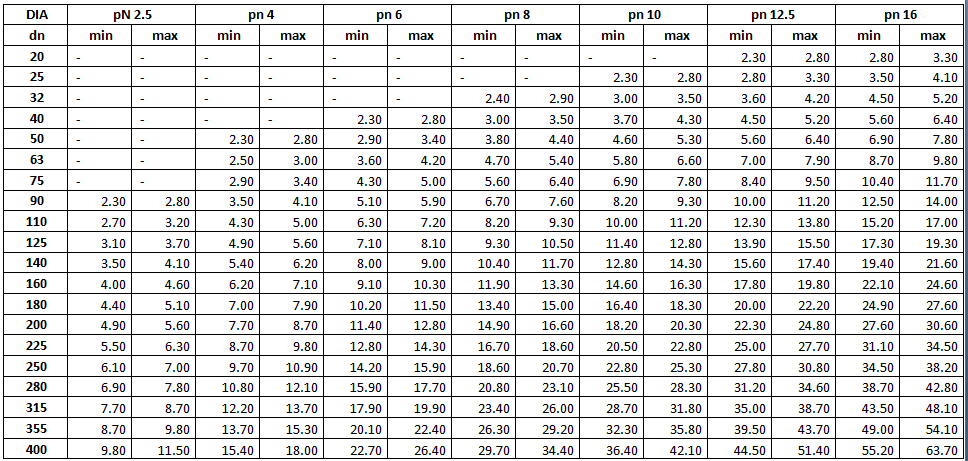

These HDPE pipes are available in sizes 20 mm to 400 mm in pressure rating of PN-2.5, PN-4.0, PN-6.0, PN-8.0, PN-10.0 , PN-12.5 & PN-16.0 in all three grades PE-63, PE-80 and PE-100.

PROPERTIES

Economical than traditional pipe material.

Resistance to chemicals- Exceptional resistance to all external and internal corrosion.

Resistant to electrolytic corrosion.

Will not rust or rot.

Welded joints speedup installation- Trench widths reduced which leads to saving in the cost of excavation and back filling.

Light weight - One sixth of the weight of steel. Low specific gravity giving an outstanding light weight product for easy transportation, handling, fitting etc.

Very good thermal insulation due to low thermal conductivity.

Smooth bore provided less head loss. Flow resistance is approximately 30 % less than that of conventional pipes, permitting the use of a smaller bore pipe for a given rate of flow.

Perfect stability of material obviates the risk of ageing.

Total neutrality to products conveyed.

Flame resistance classifying the material as self extinguishing according to test standard employed.

Low maintenance cost.

Easy to install.

Longer life than G.I, M.S cement and other pipes.

| DEPTH OF THE BORE | PRESSURE CLASS |

|---|---|

| Up to 55 Mtrs. | 4.0 kg/cm2 |

| Up to 90 Mtrs. | 6.0 kg/cm2 |

| Up to 140 Mtrs. | 10.0 kg/cm2 |

| Up to 170 Mtrs. | 12.5 kg/cm2 |

| PROPERTIES | VALUE |

|---|---|

| M.F.I. (190°C, 5kg load) | 0.20 to 1.1 gm/10 mins |

| Specified base density | 940 to 958 kg/mtr3 |

| Material Grade | PE-63, PE-80, PE-100 |

| Carbon Black | (2.5 ± 0.5%) |

| Antioxidant | <0.3% by mass |

| Tensile Strength (min) (27±2°C) | 19MPa |

| Elongation | (Testing speed = 100mm/min ± 10% ) >350% |

| Reversion | <=3% |

| Hydraulic Characteristics | No sign of localized swelling, leakage or weeping (at 80°C for 165 & 48 hrs.) |